The Measurement and Economics of Steel Construction

When humans learned to produce iron from iron ore, this changed everything, as just about anyone could create tools and weapons from iron ore, as it is far more common than copper or tin. The blast furnace was able to increase the production of iron dramatically. Preheated air at about degrees Celsius is blasted into the furnace from nozzles at its base. Contrasting with the bloomery, the iron in blast furnaces is heated to above its melting point, along with flux materials.

Flux is the purifying agent that purges the metal from the chemical impurities and allows the iron to be extracted more easily.

International Reserves External Debt. This Grade A office building was completed in Steel is strong and has a good strength-to-weight ratio. Since there is no oxygen in space, the only way our ancestors were able to salvage iron was from meteors. Economic Progress and Integration.

Flux in this case is limestone and coke. Coke is a refined bituminous coal, also known as coking coal , with very few impurities. Similar to the use of charcoal in bloomeries, coke produces carbon monoxide when burned which in turn reacts with the oxygen to remove it. The limestone reacts with the heat to create a slag of impurities that floats at the top of the blast furnace, which can then be drained away, leaving the heavier molten iron below.

Blast furnaces allowed vast quantities of iron to be produced relative to bloomeries, however, one drawback was that at high temperatures, iron reacts with carbon to absorb it, meaning that the iron produced was cast iron. Additional steps were needed to decrease the carbon content, which is called fining. The cast iron would be heated back up, oxidizing the iron, then the material would be beaten with a hammer to knock the oxidized carbon out, which was repeated until the iron was considered wrought iron.

Unfortunately, this process was fuel and labor intensive and therefore not suitable for industrial use. With the industrial revolution and the growth of rail roads, great pressure was thrust upon the iron industry to find a solution to create faster more efficient production processes. Train tracks would be needed to be replaced every weeks in some cases due to the rapid wear and tear on the soft metal. Steel therefore became the metal of choice for rail roads, as it is stronger and able to resist wear.

However, steel was still unproven as a structural metal and production was still slow and costly. With the Industrial Revolution well under way, the increasing globalization and industrialization of the world necessitated a means of mass production of steel. Henry Bessemer designed a converter in which molten iron was poured from the blast furnace. Hot air was passed through the bottom, oxygen from the air oxidized the impurities in the iron and the carbon reacted to form carbon monoxide and was expelled as a gas.

The Bessemer Process was very fast and inexpensive, unfortunately however, early on the process was a victim of its own efficiency, as it expelled too much carbon and left too much oxygen in the iron. To solve the problem, a compound was added to the process, called Spiegeleisen , which was an alloy of iron and manganese. If added in the right quantities, the manganese would react with the oxygen to remove it and the iron increased the carbon as needed. Yet, another issue arose.

Initially the Bessemer Converter could only be used with iron obtained with low phosphorus concentrations, which was scarce and therefore expensive. This process produced steel from iron ingots, also known as pig iron, in large shallow open-hearth furnaces. The process relied on heated brick chambers below the furnace to maintain temperatures high enough to burn off excess carbon and other impurities. The advantage of this method was that it produced steel in even greater quantities than the Bessemer Process; metric tons could be produced from a single furnace. Despite the slower process, the advantages proved to outweigh the disadvantages and by the open-hearth furnace had largely replaced the Bessemer Process.

The basic oxygen process BOP involves blowing pure oxygen into a blast furnace with molten iron and scrap.

This initiates a series of exothermic reactions which remove impurities such as carbon, silicon, manganese and phosphorous. Some of the commercial advantages to the BOP include high production rates, less labor, and low nitrogen steel. The leaps and bounds made in electrical engineering toward the end of the 19 th century and into the 20 th century presented the steel industry with new opportunities in steel production.

The Electric Arc Furnace EAF , which was first developed just after the turn of the 20 th century, is still used to this day. The EAF was designed to pass an electric current through a charged material, which heats the iron up to temperatures of degrees Celcius. Although originally used for specialty steels, such as steel made for springs and machinery, EAF use for long steel manufacturing, such as structural steel, rod and bar, and wire, has grown due to a number of advantages.

Steel and Bethlehem Steel. Nucor is currently one of the largest steel making firms in the U. EAFs have various other advantages. EAFs are able start and stop production as needed, something blast furnaces cannot generally do. This allows EAFs to vary production according to demand.

This greatly reduces the energy required to produce the steel compared to steel making operations from iron ore. Although EAFs usually create steel from scrap metal, molten iron from a blast furnace can also be used. If there is high production of steel, that means there is a high demand for steel, meaning the country is building infrastructure and growing economically.

But what exactly is steel used for? Steel is mostly used in construction. In its various forms and alloys, steel is designed to meet the specific requirements of unique projects. This allows steel to be incorporated in infrastructure projects in all environments. During the 20 th century with the advent of more efficient steel production processes, the railroads expanded greatly as did the advent of high-rise buildings. Steel is also used in the construction of just about anything you can think of, such as stadiums, bridges, piers, harbors, roofing, tunnels, etc.

Steel is heavily used in the automotive industry. These steels are engineering steels, which are designed to have certain specifications of elasticity, ductility, and resistance to corrosion. Steel is also used to make trucks, transmissions, trains and railways, ships, anchors, and aircrafts. The energy sector relies greatly on steel for its infrastructure.

Steel can also be used for resource extraction, such as in offshore oil rigs and pipelines, earth-moving equipment, cranes, and forklifts. In addition, the following energy projects also rely on steel, such as electricity power turbine components, wind turbines, electromagnets, transformer cores and electromagnetic shields.

Steel is used in the packaging industry, as it protects the contents of the package from the elements such as air, water, and light exposure. The majority of steel packaging is used in the food and beverage industry as well as for aerosols and closures, for example, bottle caps. You can find steel in just about any household appliance such as refrigerators, washing machines, ovens, sinks, cutlery, microwaves and the list goes on. Also, don't forget to download one of our sample reports by clicking on the button below.

Read some of our other Commodities Explainer posts: A History of Obsession - Part 1 Gold: The most precious of metals - Part 2 Gold: The most precious of metals - Part 3 Iron ore: A most underappreciated commodity Copper: The first metal mastered by man Coal: Strong fixed investment and spillovers from the expansion in the U.

Over the next few quarters, Central America and the Caribbean should continue to benefit from the booming U. Brazil's growth prospects were downgraded for the fourth month in a row. Things are looking a bit more upbeat in Mexico.

Here's our latest economic outlook for Mexico in under 60 seconds. Precious metal prices are projected to decline 0.

Monetary and Financial Sector. Economic Forecasts from the World's Leading Economists. The Story of Steel Steel is the fourth-most commonly used metal in the world. Millions of tons; Source: Steel Production History Because iron readily reacts with oxygen to produce iron oxide ores, or rust, its prevention is a constant battle.

How is steel produced today? Basic Oxygen Process The basic oxygen process BOP involves blowing pure oxygen into a blast furnace with molten iron and scrap. Electric Air Furnaces The leaps and bounds made in electrical engineering toward the end of the 19 th century and into the 20 th century presented the steel industry with new opportunities in steel production. Construction Steel is mostly used in construction. Transport Steel is heavily used in the automotive industry.

Energy The energy sector relies greatly on steel for its infrastructure. Packaging Steel is used in the packaging industry, as it protects the contents of the package from the elements such as air, water, and light exposure. Twitter FocusEconomics Strong fixed investment and spillovers from the expansion in the U. An economy on the verge of collapse? Have Cryptocurrencies Crashed for Good? Investment looks to Latin America, but forecasts are not encouraging Turkey: Erdogan has cemented his grip on power - now what about the economy?

Prelude to a Crisis? Latin America moves toward increased integration as U. How will Saudi Arabia's economy benefit from lifting the women's driving ban? Which countries are the most prepared for the upcoming digital revolution? India Under Pressure from the U. April What impact would a trade war between the U. February Regional Disparity: The story of the world's most abundant fossil fuel Venezuela's Electoral Conundrum Gold: December Increasing poverty in Latin America takes a breather thanks to improving economic dynamics What will be the most miserable economies in ?

Has Latin America gone far enough in reducing barriers to international trade? Economy at a tipping point?

How is steel produced today?

Is the UK really "shackled to a corpse"? Which countries will have the highest and lowest inflation in ? As long as recycling continues therefore, the life of a steel product is, in effect, infinite and individual incarnations or uses of a steel product, are merely parts of the larger life cycle of the material. For example, by only considering the recycling step but excluding the initial, generally larger, impact from the initial primary production.

This is further explained here. Steel recycling rates vary by country and product type. Two UK studies have been undertaken to estimate the recycling rates of structural steel. Steel is strong and has a good strength-to-weight ratio. Compared to other commonly used, structural materials, steel buildings are lightweight meaning that significantly fewer materials are required to construct them.

Not only does this reduce the weight and the environmental impact of the above ground structure, but importantly, it can also reduce foundation loads meaning that fewer and smaller foundations are required compared to heavier structural forms. As part of the Target Zero study , the weights of equivalent steel and concrete-framed buildings were compared.

The building on which the office building research was based is One Kingdom Street, located in the Waterside regeneration area near Paddington railway station in Central London. This Grade A office building was completed in The building was designed to achieve the maximum floor plate depth consistent with British Council for Offices BCO guidance.

Two structural forms were compared:. The figures below show the mass of materials used to construct each of the two office building alternatives, broken down by building element and material type. The total mass of materials used to construct the office building was Compared to the base case building, the post-tensioned concrete building Option 1 requires an additional 25,kt of concrete. For further information and results see the Target Zero office design guide.

Material efficiency is an integral part of the modern steelmaking process. The goal is to use all raw materials to their full capacity and eliminate waste from steelmaking. This approach includes industrial symbiosis in which almost every by-product formed during steelmaking is used in new products. This minimises the amount of waste sent to landfill, reduces emissions, and preserves raw materials. As with all large-scale manufacturing processes, the production of iron and steel generates by-products.

Slag is used to make a range of products including cement, fertilisers, and asphalt. Process gases from iron and steelmaking are typically used within the steelmaking plant, replacing steam and electricity, or exported to the local grid. Other by-products such as dust are reclaimed for their high metallic content. Structural steel sections are inherently reusable.

Reuse , as opposed to the current, common practice of recycling structural steel by remelting, offers significant potential in terms of resource efficiency and carbon emission savings.

- .

- Steel and the circular economy - bahana-line.com.

- .

- Triumph of the City: How Urban Spaces Make Us Human.

- SteelConstruction.info.

There are many steel-based temporary works systems which are highly reused see below ; the challenge it to develop permanent works systems that are similarly reusable. Reusing reclaimed structural steel is not a new idea; in fact, the practice was more prevalent in the past but has declined over the last few decades. There are several reasons for this the most significant including new development programme constraints and tougher health and safety requirements in relation to demolition activities, in particular, working at height.

Reuse is technically viable, as demonstrated by isolated projects and in certain niche markets, but there are barriers. Reusing simple, low-rise structures such as portal frames , is relatively common particularly in the agricultural sector. Larger, whole building reuse is less common other than in-situ refurbishment but there are some examples, such as the SEGRO case study , where this has worked well under certain scenarios. Some steel stockists offer reclaimed steel sections alongside new steel and others offer excess, unused steel tube from the offshore industry for use in the construction industry particularly for piling.

The SCI, working together with the University of Cambridge, has recently completed two research projects into structural steel reuse exploring the barriers to more mainstream reuse, the economics of reuse and assessing the feasibility of developing a website for trading and sharing information about reclaimed structural steel. Although more mainstream structural steel reuse is unlikely under current UK economic and legislative conditions, BIM technologies overcome several of the barriers to steel reuse by providing certainty about material properties, traceability and provenance and eliminating the need for testing.

Looking ahead therefore, structural steel BIM models offer a cost effective means of enabling future reuse. Steelwork contractors have been using BIM models for years and routinely offer their clients as-built structural models on building handover. By storing such models in a secure database, this will future-proof UK steel structures and will assist with refurbishment, extension and eventually deconstruction of the building to facilitate reuse of the steel elements or optimising the recycling process.

The UK steel construction sector is exploring how to provide a service to do this. Extending the life of buildings is another key component of the circular economy. This can be achieved by making buildings that are both flexible and adaptable to change so that they last longer and greater value is extracted from the materials and resources used to construct them. The pace of change in all walks of life has never been greater.

Changing work patterns, new building services and information technologies, changing demographics and new legislation are all putting new and different demands on buildings. Sustainable buildings should be flexible to change of use and adaptable to future needs and requirements be they regulatory or market driven. Difficulty in adapting buildings to change often leads to their premature redundancy and subsequent demolition. Even before redundancy, failure or inability to adapt and upgrade buildings can compromise occupant comfort and, in commercial buildings, reduce their productivity.

Although the definitions of adaptability and flexibility are often blurred, the following definitions are generally adopted:.

The Story of Steel

In addition, adaptable buildings should be designed to be able to accommodate the predicted impacts of climate change, for example higher temperatures, higher and more concentrated rainfall and more frequent and severe storm events, including flood resilience. The useful life of buildings can be extended through the adaptation and reconfiguration of internal space and walls, structural extension and upgrading of the external envelope, etc. In these ways the life cycle costs and the environmental impacts of the building are reduced as more value is obtained from the same resources.

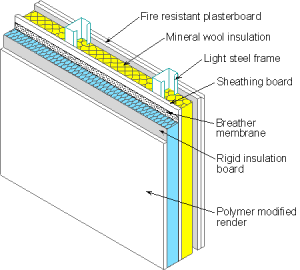

Steel-framed buildings are among the most adaptable and flexible assets a business can invest in. The steel frame itself can be easily adapted, with parts added or taken away, and its light weight means that extra floors can often be added without overloading existing foundations. Steel structures are commonly used to renovate buildings for example behind retained facades.

Kinnaird House below was constructed in the early s using Portland stone held in place by an integral steel frame. The client's main criterion for the redevelopment was that the existing character of the building should be maintained while maximising the net lettable floor area. This was achieved using a shallow floor system , tied to the original steel stanchions, and lightweight concrete on steel decking.

The consequential reduction in load carried by the foundations enabled an additional floor to be inserted into the old banking hall area and an extra floor to be added for plant at roof level. The shallow floor construction also allowed an unhindered services zone across each floor plate. Shallow floor system behind the retained facade. The large column-free spaces created by long span steel sections mean that buildings can be constantly adapted to cope with the changing requirements of its occupants. Building interiors can be easily and economically adapted, avoiding the high costs of redevelopment or demolition.

Having fewer columns provides a major benefit to building owners and users, as it is easy to subdivide space or alter it in any way that changing circumstances demand. In competitive property markets open spaces provided by constructional steelwork allow premium rents to be charged.

Eleven large trusses support the roof and create 55m-wide column-free space that provides flexible space that can be reconfigured or changed using movable partition walls. Steel frames also offer many solutions to integrate building services within the structural floor zone including systems such as shallow floor construction and long-span beams with regular or tailor-made openings in the beam webs.

The basic decision to either integrate the services within the structural depth or to suspend the services below the structure affects the choice of structure, the fire protection system, the cladding details and the overall building height. There are two general approaches to design to accommodate the horizontal distribution of services:. Flexible services distribution has a double benefit, initial design and construction programming is made easier since the structural design and fabrication can be progressed before the precise service requirements and routing is finalised.

Also the building is more adaptable to meet future servicing requirements resulting from, for example, a change of use or tenant or simply to upgrade the services. More detailed guidance on service integration within steel-framed buildings is available. Design for deconstruction and reuse is an important discipline in sustainable construction and central to the circular economy. Only by designing buildings for deconstruction can we make reuse of building components more commonplace.

The ability to reuse building components is, to a large extent, dependent on how buildings have been constructed in the first place. Although designers routinely consider the constructability of buildings, historically little thought is given to their deconstruction and how elements and components could be reclaimed and reused.

This can be achieved by ensuring that components that are specified can preferably be reused rather than recycled or downcycled at the end of their life; maintaining their value. DfD is one of the key parts of the jigsaw to assist the construction industry in achieving higher levels of resource efficiency and embedding circular economy thinking. Consideration of DfD needs to be embedded within the key stages of the design process to ensure it is considered at the earliest stages of a construction project where the opportunity for influence is at its greatest.

Common principles to follow in design for deconstruction and reuse are:.